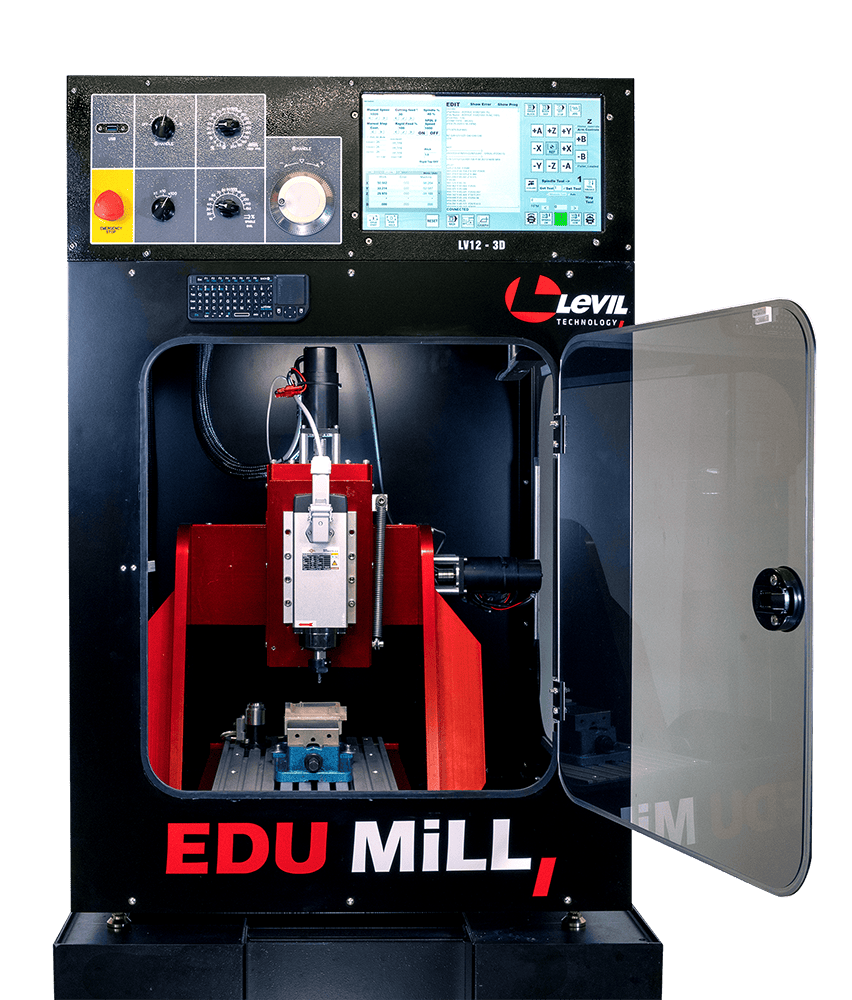

LOW-INERTIA CNC MACHINE WITH METAL 3D PRINTING

Flexibility. Adaptability. Affordability.

The EDUMiLL is a revolutionary system that incorporates technologies from the additive and subtractive manufacturing fields to open the door to a new world of possibilities and further innovation by making it affordable to include a 3D printer and a robust CNC mill in one package

Cutting video samples

Specifications

Spindle

3D Printing System Add-on

Fused Deposition Modeling (FDM) or Fused Filament

Fabrication (FFF)

WE BRING METAL TO YOUR WORKSPACE

Design, print, sinter in a few steps. 3D-print real metal parts affordably and in the comfort of your home, office, or lab. You can now print metals such as Bronze, Copper, and Stainless Steel.

Filaments

Our kilns for sintering

STARTER KILN

PRO KILN

3D Print Metals with Levil Technology

Create strong, durable, functional parts using any FDM printer. Print & sinter from anywhere!

Metal 3D printing using Fused Deposition Modeling (FDM) is a groundbreaking technology that forms intricate and sturdy metal parts by melting and layering metal filaments. This technique is becoming increasingly popular in numerous industries, including education, due to its ability to produce top-quality parts rapidly and affordably.

In educational settings, FDM metal 3D printing offers students practical experience in designing and crafting metal elements, fostering essential skills for future professions in engineering and manufacturing.

Moreover, it presents new avenues for research and experimentation, empowering students to investigate the capabilities of metal 3D printing technology.

We have it all!

Everything you need to print & sinter metal 3D printed parts.

Transform your concepts into tangible objects, be it for manufacturing, prototype development, or pure enjoyment. The EDUMiLL enables you to 3D print with a variety of materials, including aluminum, stainless steel, and Inconel. Metal 3D printing represents the future and is here to remain; moreover, it has become increasingly accessible and cost-effective.

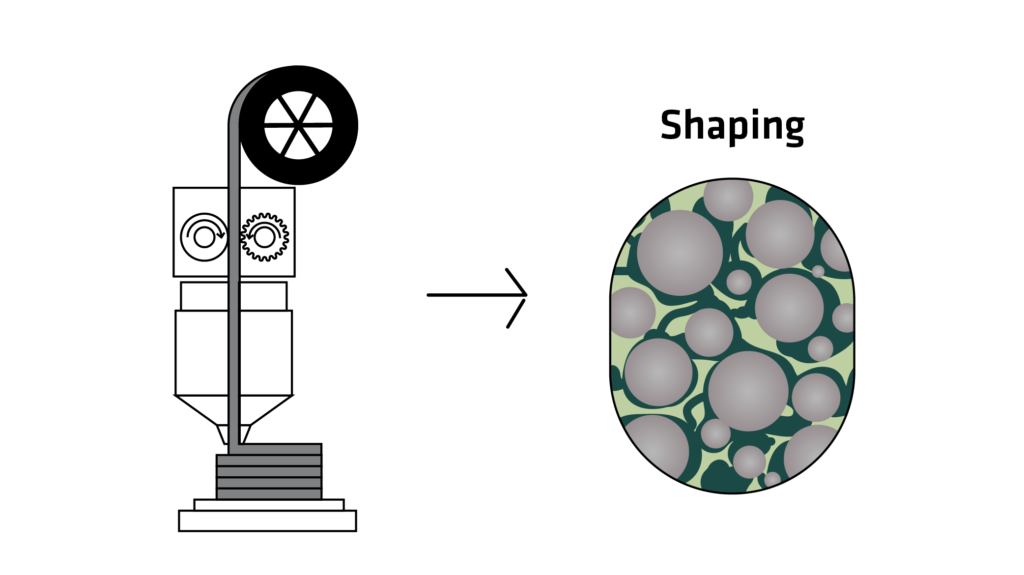

This filament, similar to regular PLA, is loaded into a 3D printer and used with FFF 3D printers. Instead of pure plastic, the printer layers a binder mixed with metal, which temporarily supports and positions the metal particles.

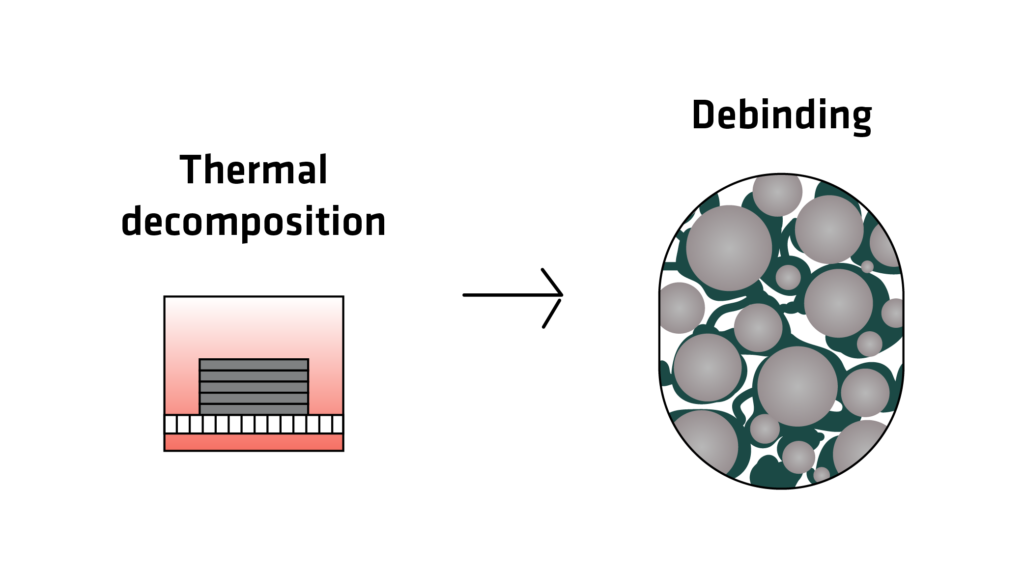

After printing, the part undergoes a heat treatment debinding process to remove plastic or wax binders from the “green part,” creating a porous structure for sintering, resulting in a strong, dense metal component.

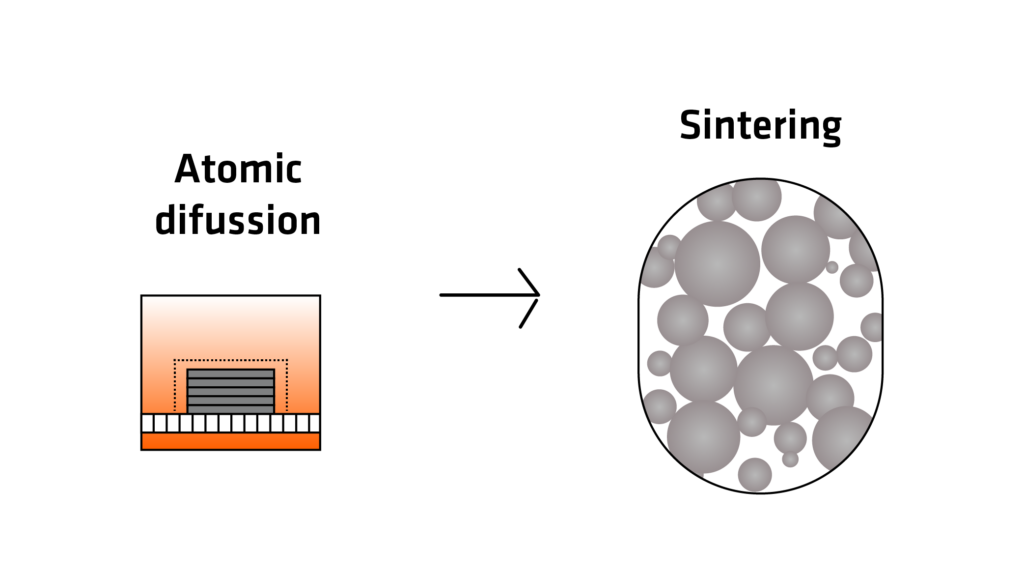

The printed part undergoes high-temperature heating, fusing metal particles into a solid, dense component, yielding a final product that is both robust and compact.

Get a quote